Vision

Precision Sand Control at your fingertips

Foundries face rejections even though sand parameters are maintained well within their control ranges. Due to the huge interdependencies that exist between parameters, there is a need to understand this relationship via an optimal system.

Establish correlations & identify interdependency

Differentiates Anomalies & Outliers

Digital Twin to simulate scenarios

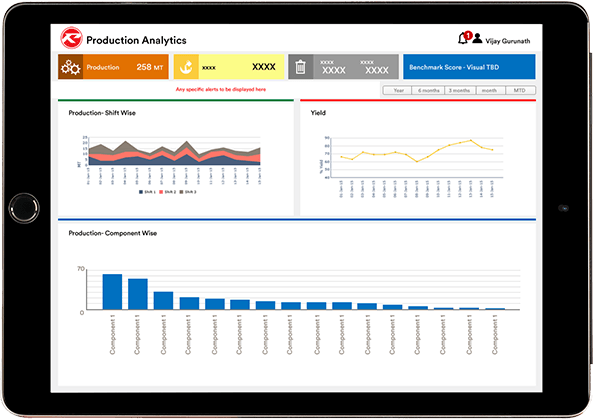

Multiple Dashboards

USP

Foundries currently use Statistical Process Controls (SPC) for controlling the parameters. This is often misleading in a foundry setting due to the data not being independent and identically distributed. Data in a foundry is not independent and exhibits a time series effect.

Refcoat™ has built a system that recognizes all this - OGSS.

OGSS is our web portal that uses mathematical transformations on data, establishes correlations amongst data points and helps identify the interdependency. This not only provides an unbiased wholistic approach towards scenarios, it helps differentiate between anomalies and outliers.

OGSS will be a Digital Twin for your sand plant so you could simulate scenarios and view changes even before they are made. It prepares you to take pro-active control rather than reactive control. Equipped with multiple dashboards for sand, process, production and rejection management, OGSS provides precision sand control at your fingertips round the clock.