Vision

Empower foundries produce better casting at a lesser cost while being environmental friendly

High-Performance

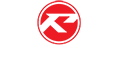

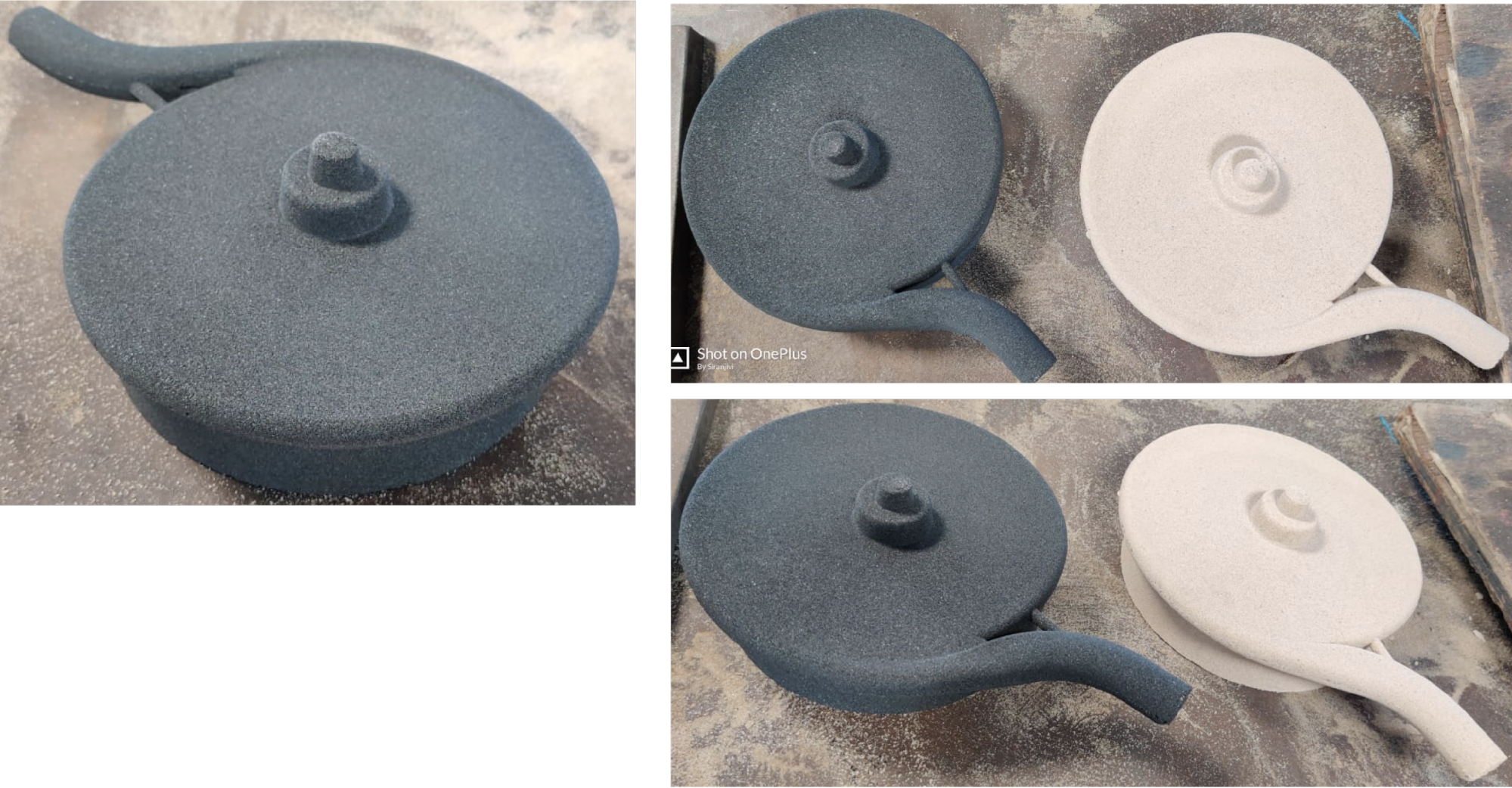

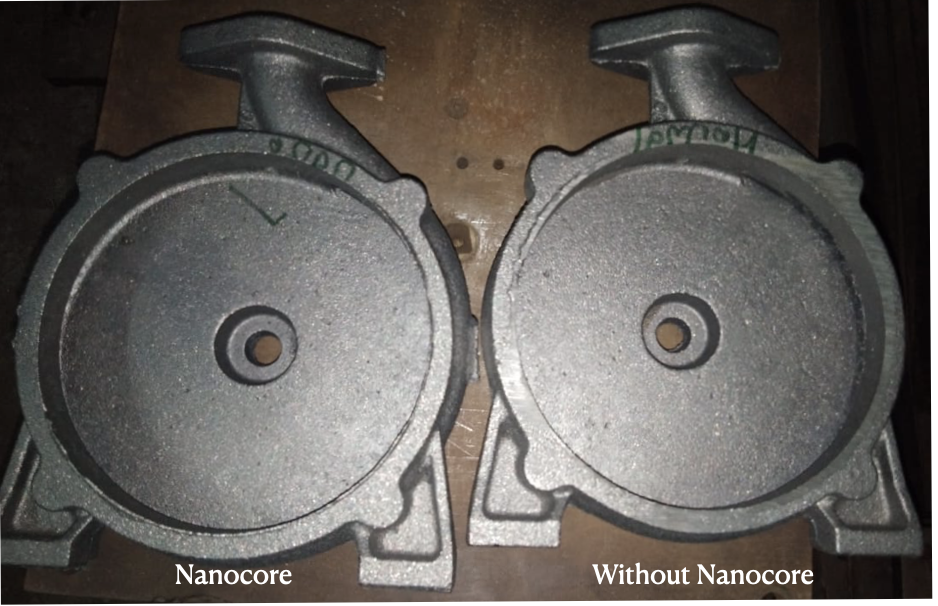

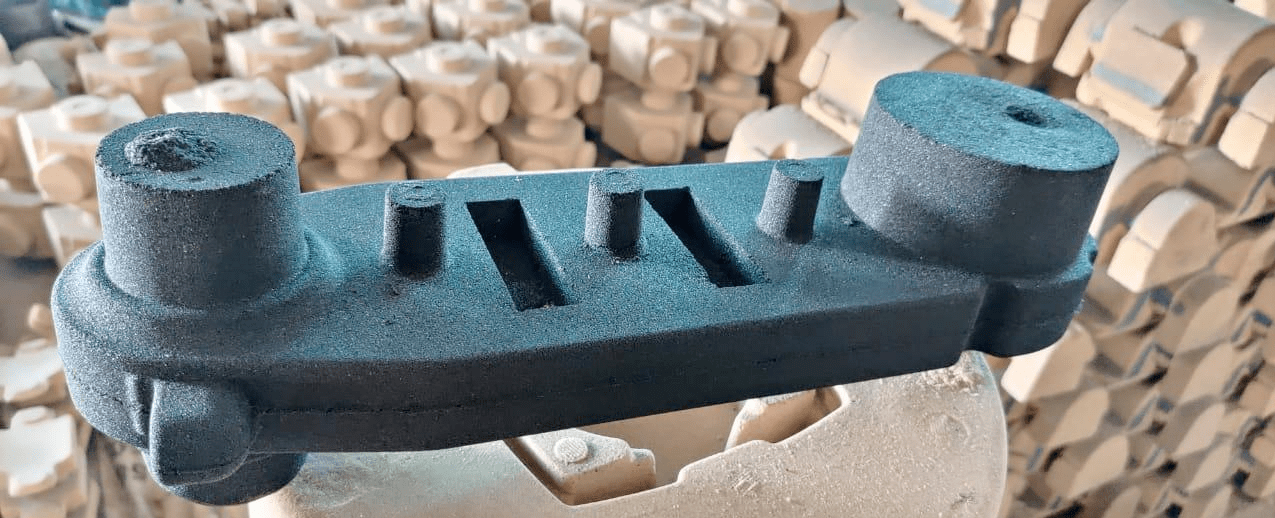

Supreme Surface Finish

Coating replacement

Nanotechnology

USP

100% elimination of refractory mould and core coatings. Ultimate surface finish with just 0.3% Nanocore. A paradigm shift in metal-sand barriers brought about with our nanotechnology-based product.

Nanocore technology

Nanocore Properties

With almost 0% Volatile Matter @ 400℃, we have drastically reduced VOC

Nanocore Advantages

Ultimate Surface finish