Vision

Creating Ultimate Value

Rapidly activate bentonite, reduce rejections, and optimize foundry processes, all while championing environmental sustainability.

Advance bentonite activation

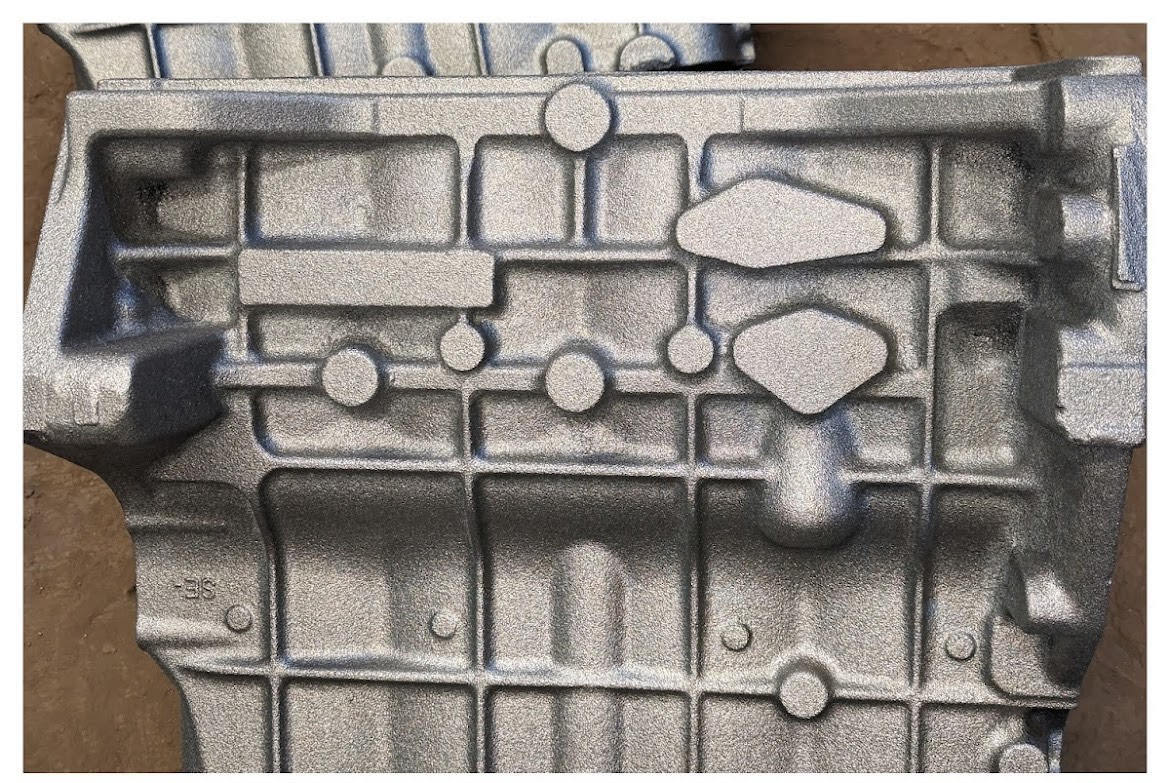

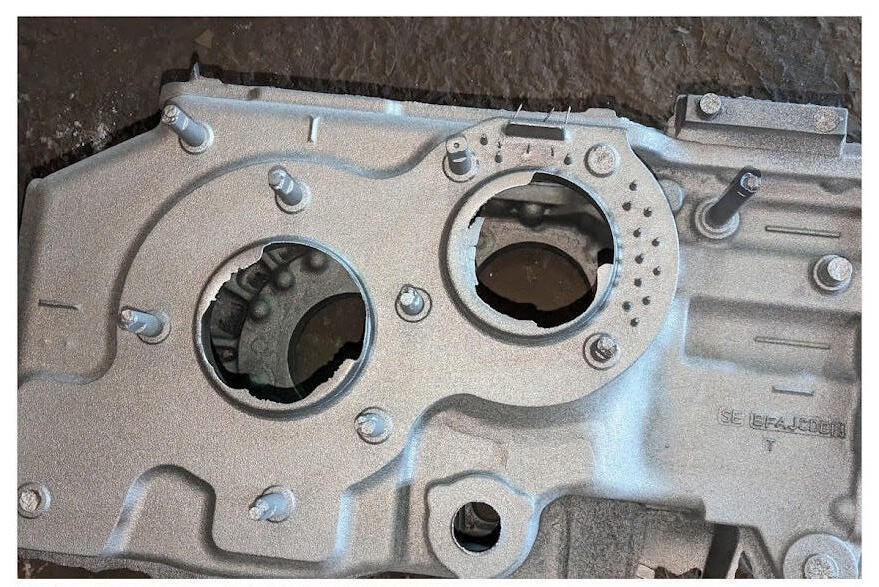

Zero Green Sand rejection

Catalyst for bentonite – water interaction

Additive for water

USP

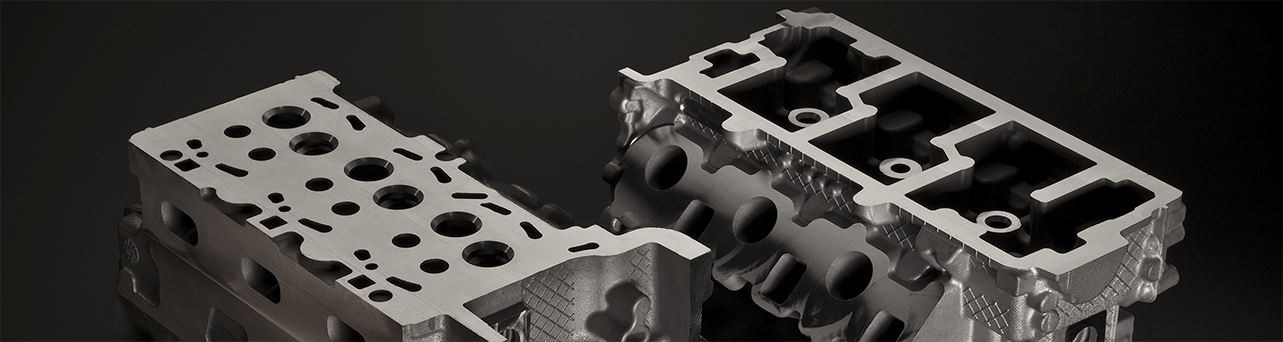

In the intricate dance of metallurgy, every casting, every mold, every grain of sand matters. We don't just offer products; we offer value – the ultimate value. MouldMax is more than just an innovation; it's our way of redefining the boundaries of what's possible in foundries worldwide.

Mouldmax Advantages

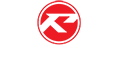

Ultimate Surface finish