Vision

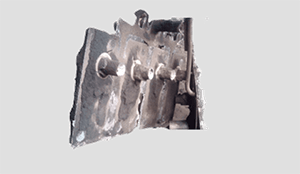

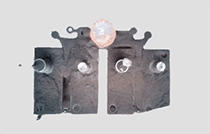

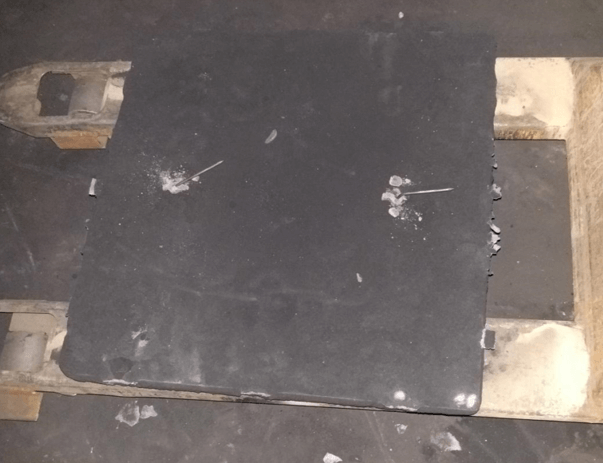

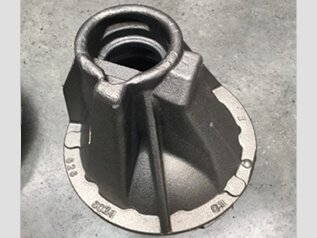

Imparting a superior finish on the castings

Eliminating metal penetration and burn-on defects, our revolutionary new technology reduces rejection rate and helps you maximize cost efficiency.

Nanomaterials

Anti-Scabbing Agents

Carbon

Proprietary blend

USP

A revolutionary new technology that combines scientifically selected nanomaterials, anti-scabbing agents, carbon, and a proprietary blend that form a ceramic surface where molten metal meets sand. Experience a superior surface finish with our proprietary technology!

Cerakarb technology

Cerakarb Advantages

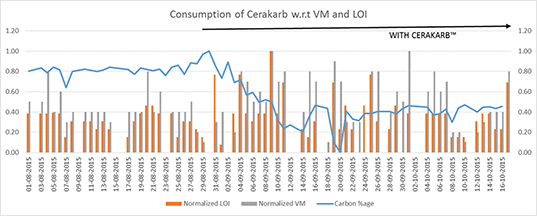

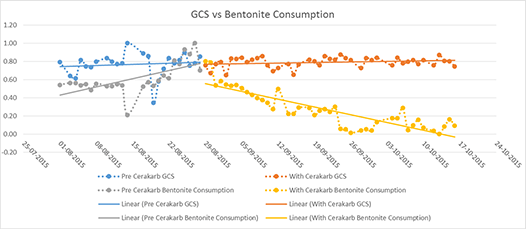

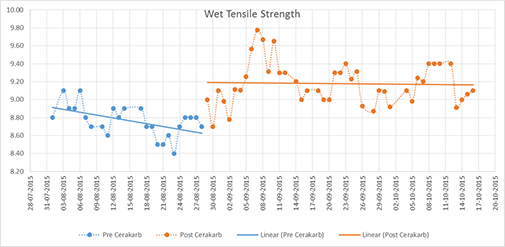

Cerakarb graphs

Reduced Bentonite Consumption without affecting GCS

Increased Wet Tensile Strength

Reduced Carbon Consumption