Vision

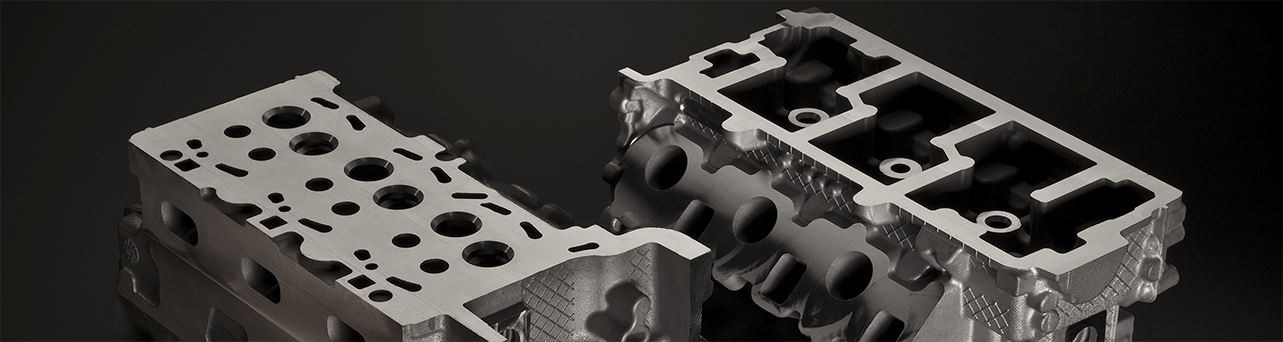

Deliver the ultimate finish on your castings with almost immediate results

High-Performance

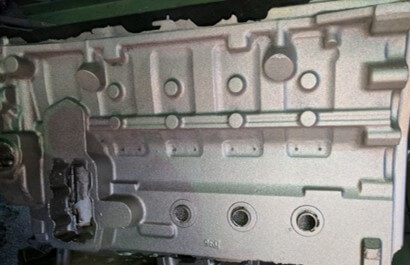

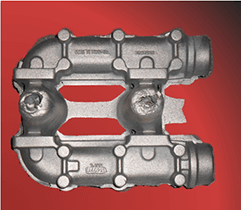

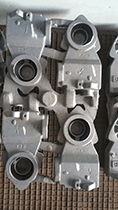

Supreme Surface Finish

Carbon Additive

Nanotechnology

USP

Questioning the status-quo at every stage of development, we set out to develop a revolutionary new age material in Nanokarb. A high performance material that can be used along with your existing carbon additive or as its replacement - Nanokarb ensures supreme finish on your castings in record time!

Nanokarb technology

Nanokarb Properties

With almost 0% Volatile Matter @ 400℃, we have drastically reduced VOC

Nanokarb Advantages

Ultimate Surface finish